The Village of Salem Lakes is located in Southeastern Wisconsin, encompassing roughly 30 square miles of land and 3 square miles of water in Kenosha County. With a population around 14,000, Salem Lakes is known for its scenic lakes and small-town charm, which make it both a pleasant place to live and visit. The village’s water system serves a small portion of the overall village, with only commercial type users; all residential homes remain on private wells. Customers served by the water system include a business park, fire department, surrounding farms, contractors, railroad, and others who rely on the system to fill tanker trucks.

Comprised of one 250,000-gallon elevated storage tank and one deep well (Well No. 1), the village had three primary concerns with its existing system:

- With only one well, there was no redundant water supply. While the village’s system classification didn’t require it, the lack of redundancy concerned the village from a risk and resilience perspective—particularly for keeping the business park online and, more importantly, for fire protection needs.

- Following its construction in 2010, the existing Well No. 1 had elevated combined radium levels in excess of the maximum contaminant limit (MCL). Similar to the redundancy issue, the village’s classification did not require levels under the MCL, but the village did not want to bear this concern for its water consumers.

- Low water turnover in the large, elevated tank created seasonal issues. During the winter, tank water would freeze, creating an ice sheet with the potential to damage the inside of the tank. In the summer, elevated temperatures created water quality issues. The village’s solution was to send operators out to open hydrants and flush water, potentially exposing them to extreme weather conditions.

To resolve these problems—and prepare for anticipated expansion into a fully regulated community system in the coming years—the village needed a cost-effective solution. They turned to Foth, tasking our team with developing a single project to address all concerns.

Improving Redundancy

Improving Redundancy

Typically, adding a second well is an easy solution to redundancy problems; in this case, adding a well (Well No. 2) was challenging. To avoid the same radium concerns as Well No. 1, Well No. 2 needed to be a shallow aquifer well; however, in this part of Southeastern Wisconsin, production capacity of such wells tends to be very low. Higher production shallow wells can only be found where underground gravel veins are present, but such veins are hard to find.

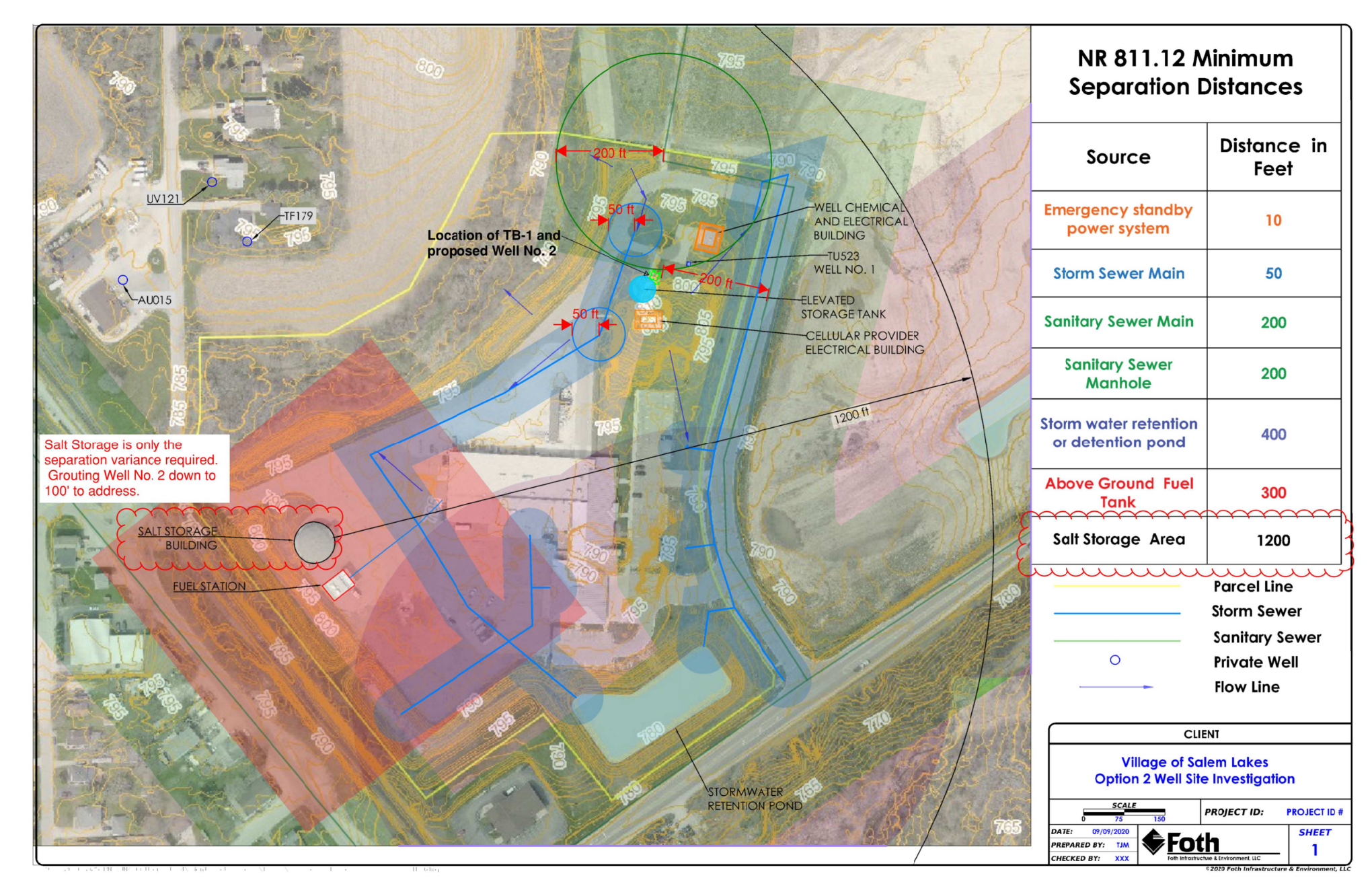

As a cost-saving measure, we sought to site Well No. 2 close to Well No. 1, allowing for the existing electrical, control, and chemical feed systems to operate both wells. The site had many challenges for a shallow well—mainly due to the close proximity of a salt storage facility, above ground fuel storage tank, stormwater pond, sanitary sewer, and storm sewer. Only a few small areas of the site were viable and required a variance from the DNR for the salt storage facility, which included special design provisions for Well No. 2 to ensure no influence by high salt content in shallower soils.

Following DNR approval, we moved forward with test boring, which passed through a large gravel vein near the bottom of the shallow aquifer. Test pumping indicated a high specific capacity and water quality tests showed extremely low radium levels. Given the great capacity and quality results, this became the permanent site for Well No. 2.

Lowering Radium Levels

Prior to beginning this project, the village had evaluated four options for reducing combined radium residuals from Well No. 1: radium absorptive media, hydrous manganese oxide (HMO) and filtration, ion exchange softening, and blending water from Well No. 1 with another source. Following successful siting of Well No. 2, blending water from the two wells was identified as the best solution from an initial cost and long-term savings standpoint.

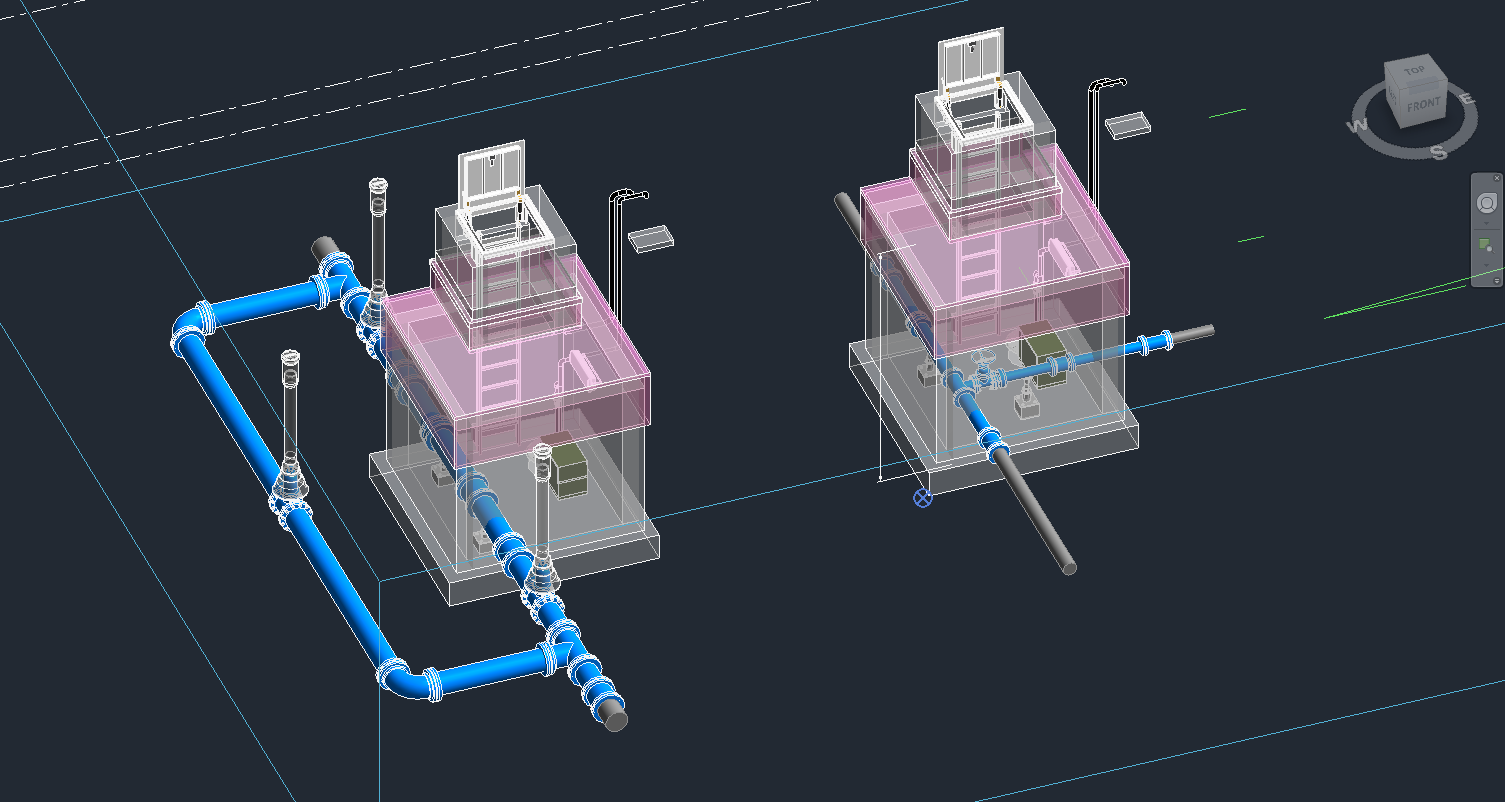

Our team designed an innovative blending vault to combine the water, with a control system that meters the flow rate from each well and flow-pacing that achieves a set blending ratio safely below the MCL. This solution utilizes Well No. 2’s excellent water quality to save the village an estimated $1.5 to $2 million by avoiding the need for a water treatment plant. In years to come, further savings will be captured through elimination of the need for the expensive treatment chemicals and additional associated treatment system maintenance.

Improving Tower Turnover

Solving temperature-related tank issues required a Foth-developed, custom solution that allowed operators to monitor tank temperature and automatically flush the tank remotely from a smart phone or tablet. To achieve this, programming was added to the SCADA system providing an operator interface screen showing tank temperature, automatic flush setpoints, and flush volumes.

Once the programming piece was determined, the greatest challenge was transporting the high volume of flush water. The storm sewer system adjacent to the water tower flows directly to a retention pond about a quarter mile away and was identified as the best option, following proper permitting with the DNR. With a small extension of the stormwater system, a collection pipe and manhole were placed directly under the tower’s overflow pipe to capture and convey flush water. The flush is controlled through a unique connection to the outlet pipe within the base-cone area that includes piping connections and fittings, a flow meter that measures both flow rate and volume, and an electric actuated valve. A submersible mixing system was also added inside the tank to help optimize water turnover and quality.

New SCADA programming prevents the wells from running while a flush sequence is occurring. Once the sequence is complete, the wells run and refill the tower with new, 55-degree groundwater—either warming or cooling the tank, depending on the season.

Environmental, Social, and Community Benefits

Impacts to the community if the water system goes offline are significant. By creating supply redundancy through the addition of Well No. 2, the water system is more reliable, allowing local businesses, farmers, railroad, and contractors to maintain their daily water needs and ensuring adequate supply is available for critical areawide fire protection.

Impacts to the community if the water system goes offline are significant. By creating supply redundancy through the addition of Well No. 2, the water system is more reliable, allowing local businesses, farmers, railroad, and contractors to maintain their daily water needs and ensuring adequate supply is available for critical areawide fire protection.

Addressing the high radium concern in the water provided immediate health benefits to consumers, and utilizing a blending method for lowering the level was the most economically and environmentally friendly solution for doing so. Traditional radium treatment methods, like HMO or ion exchange, utilize significantly more chemicals and produce substantial waste streams that the village would have to address. Avoiding the high costs and added wastes associated with chemical treatment provides both environmental and social benefits to the village. It also means that, as the system grows and its classification changes, the path forward is simpler.

Automatic water tower flushing keeps operators safe in their homes during dangerous, frigid cold conditions and extreme heat conditions. It also saves labor costs incurred through manual flushing, which typically required hours of overtime in the field, and prevents tank damage associated with ice buildup. Such damage can lead to premature tank rehabilitation when coatings must be replaced.

Summary

The project was made possible through creativity, innovation, and excellent communication between the village, Foth, and DNR staff. In addition to the three primary goals of the project, this project saved the village millions of dollars by utilizing smart, economical design solutions and will continue to yield savings for the foreseeable future.

Markets: Municipalities

Services: Drinking Water, Water Treatment Design

Related Insights

Customized Solutions Create Modern, Reliable Drinking Water System

8.30.2024 | Dale Broeckert, P.E.