Background

In the highly competitive beer market, it is critical to move product out of the brewery and into distribution channels as efficiently and effectively as possible. As one of the largest beer companies in the world, our client wanted to increase warehouse capacity and productivity at one of their breweries to better keep up with their desired output and efficiency.

Approach

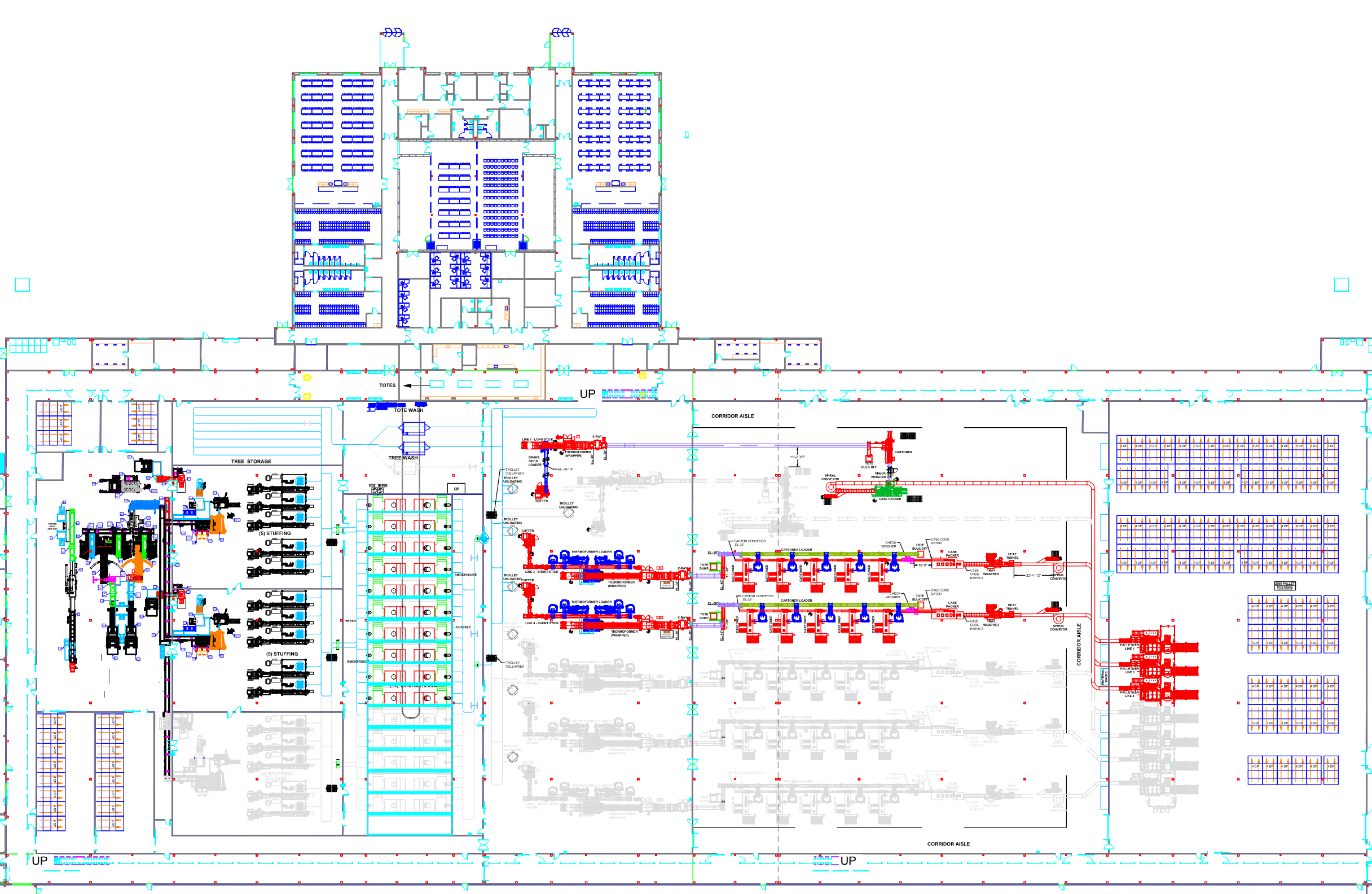

To meet our client’s goals, the project plan called for updating and replacing the automated warehouse equipment and navigation technology with more optimized solutions. In addition, it would be necessary to modify existing palletizers and conveyors, replace a battery charger, and repair sections of the warehouse floor.

To plan and execute this project, we engaged a team of controls, packaging, and structural engineers, as well as construction and project managers, and distribution and logistics technology experts.

The overall project objective was to remove the aging LGVs and replaced them with faster, more efficient, and more reliable systems and new outbound key conveyors. This change allowed for double picking and ultimately created a more space-optimized warehouse.

To keep up with the desired level of inventory, we modified the ASRS programming to integrate with the new system and LGVs, and with the client’s existing system.

The demands of the client’s production schedule allowed for little available time for our team to work in the warehouse, which challenged the team to be flexible and efficient to complete the project deliverables on time.

Results

Efficiency and capacity at the updated brewery have been boosted as a result of the integrated new equipment and a newly refinished warehouse floor, optimized ASRS, and improved conveyance system.

Our project team was applauded by the client for project execution and its flexibility and willingness to work around a demanding production schedule. We also earned kudos for maximizing efficiencies and coming in under budget in a few areas of scope.

Markets: Consumer Products, Food and Beverage, Manufacturing and Industrial Products

Services: Distribution Logistics Technology