Lead Mechanical Engineer Joseph Spychalla describes how Foth’s Automated Manufacturing Solutions (AMS) process and proof of principle phase accelerates production innovation by mitigating risk to produce first-of-a-kind solutions in the article “Proof of Principle Accelerates Production Innovation” published by Industry Today.

Read an excerpt below.

Proof-of-Principle Accelerates Production Innovation

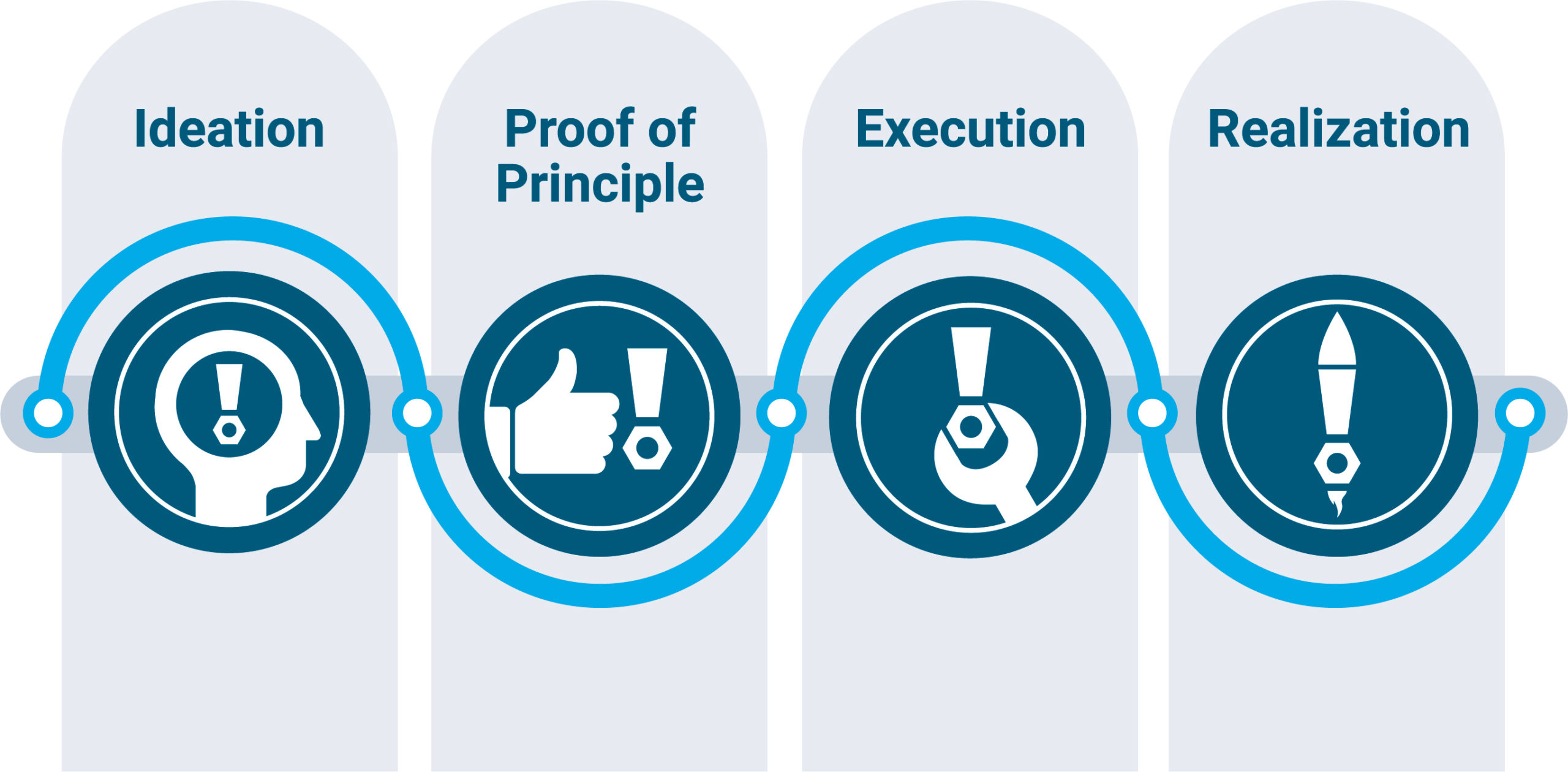

Taking the proper steps to prove a concept works is common to most manufacturing innovation processes. Some projects require special rigor, especially when the challenge at hand requires a first-of-a-kind solution. That’s why Foth has developed its own dedicated process to establishing Automated Manufacturing Solutions (AMS).

The beauty of the AMS process is that it focuses a team’s attention on the most critical aspect, requiring a resolution to the trickiest problem first, before addressing other important aspects of the solution.

Starting with the End in Mind

The foundation of the four-step AMS process is the client’s primary business goals. Unlike routine equipment upgrades and additions where the concept has been well documented and scoped, the AMS process starts with a challenge or goal for which there is no immediately available solution.

Read the complete four-step roadmap in the full article.

Joseph Spychalla combines more than 20 years of conceptual and detailed mechanical design and development engineering experience with project management excellence to consistently deliver the best possible automation solutions. Joseph has successfully led projects developing first-of-a-kind machines for both industrial automation and aerospace electro-mechanical actuation. While focused on the entire project lifecycle, including manufacturing, assembly, and installation, Joseph has a particular interest in the development of prototypes, machine testing, and the proof-of-principle process.

Related News and Events

Foth and Salem Lakes Win Small Project of the Year for Water System Improvements