WE BELIEVE:

“No job is so important, and no work is so urgent that we cannot take time to perform our work safely.”

A rigorous and unfailing focus on health and safety provides lasting value for our clients and reflects our care for our members. We do more than just perform our work safely. We design safety into our work, so our clients and communities will continue to benefit long after we have completed their projects.

Health and Safety Affiliations and Certifications

Recognized for Our Commitment to Safety

Aon Safety Gold Excellence Award, Wisconsin Safety Council Corporate Award, and Minnesota Governor’s Award for Safety are just a few of the recent awards Foth has received for excellence in safety. We make safety a priority to keep our members and our clients safe, being recognized for these efforts affirms our commitment and helps us strive for continuous improvement.

Member Safety

Establishing a strong safety culture is fundamental. Foth’s safety culture promotes awareness, responsibility, and accountability for safety at all levels of the organization.

Foth has created an environment where, without hesitation, our members feel empowered to report hazards or potential risks and are supported in making decisions that put safety paramount above all other considerations. It is ultimately the decisions made and actions taken by our members that have led to our long-sustained success in safety.

Client Safety

We are a safety partner for our clients. We understand our clients’ requirements for compliance and incorporate them into our own rigorous safety plans. Through knowledge of and adherence to the latest industry standards and regulations, regular risk assessment, proper documentation, and frequent communication, we create a transparent safety culture for our clients, bound by continuous improvement and accountability.

Harnessing Innovation for Enhanced Safety

We invest in the latest technology and personal protective equipment to keep our members and our client sites safe.

Our augmented reality, virtual reality and drone fleet keep our members out of harm’s way, while still getting the data and results they need to complete projects on time and within budget.

Safe Project Highlight

The Conagra Brands vegetable-processing plant in Waseca, Minnesota had reached the end of its useful life and the company had decided it would be more cost-effective to build a new plant instead of refurbishing the existing one.

With an average of nearly 250 contractors on site each day and more than 1,100 people involved overall, it’s plain to see how a single point of contact simplified Conagra Brands’ risk management responsibilities and general oversight of the build.

While the main project goal was to engineer a facility capable of producing a high volume of product throughput, the health and safety of the people involved was of paramount importance. Over the duration of this engagement, Foth was responsible for the well-being of more than 1,100 individuals who combined to log nearly 700,000 safe working hours.

Project Specs

- $250+ million project

- 245,000 square feet

- 1,100+ people worked on the project

- 250 contractors on site daily

- 688,618 safe working hours

Reach Out to Learn More

Chris Seider, CSP, PHR, CHST, ARM

Director of Health and Safety

Email: chris.seider@foth.com

Ph: 920-497-2500

Director of health and safety, Chris provides safety leadership for Foth’s 670+ members across 29+ locations and has over 18 years of experience in the safety industry. He delivers technical safety expertise across multiple disciplines, including compliance, permitting and remediation; mechanical, electrical, process and structural engineering; and project management. Chris directs construction management safety for multi-million-dollar construction projects across multiple states and also guides and oversees safety risk assessments for custom machine designs.

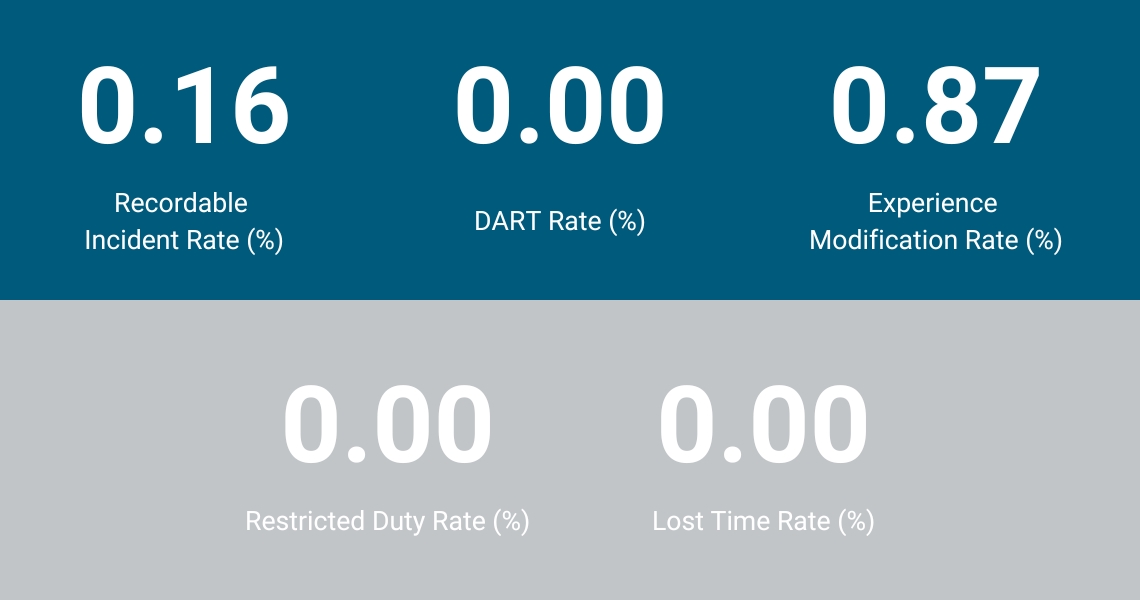

Under Chris’ leadership, Foth has maintained a total recordable incident rate below 1% and over 11 years without a lost time or restricted duty incident (over 13 million hours).

Ted is a corporate safety specialist with over four years of experience in heavy industrial construction, window manufacturing, and packaging. His passion for workplace health and safety stems from a personal connection — his own (minor) workplace accident at a young age, which left a lasting impact. Some of Ted’s current roles involve tracking safety data and metrics, contractor management and compliance, conducting health and safety plan audits, enhancing safety programs and tools, corporate safety communication, member training, and personal protective equipment management. He’s an accredited safety professional who combines practical expertise with a genuine commitment to improving safety culture.