In the world of manufacturing, the word custom is often affiliated with big risks and high costs. Serial 1 Automation is changing that. Now you can accelerate the pace and limit costly mistakes by derisking the process of custom automation.

When it’s time to upgrade your production line, but an off-the-shelf solution doesn’t exist, the Serial 1 team creates first-of-a-kind solutions that become yours to own.

Redefine Custom with First-of-a-Kind Solutions

Common challenges that are candidates for automation:

- Labor shortages

- Throughput increases

- Material availability challenges

- Evolving consumer trends

- No off-the-shelf solution exists

Watch Andersen Corporation's Serial 1 Automation Journey

How Serial 1 Automation led Andersen Corporation to discover the manufacturing model of the future:

Challenges:

- Growth in consumer demand

- Limited manufacturing capacity

- Limited equipment-building resources

Outcomes:

- New 550,000 sqft. manufacturing facility

- 175 individual assets designed, build and installed

- Supply chain optimized

- Waste footprint minimized

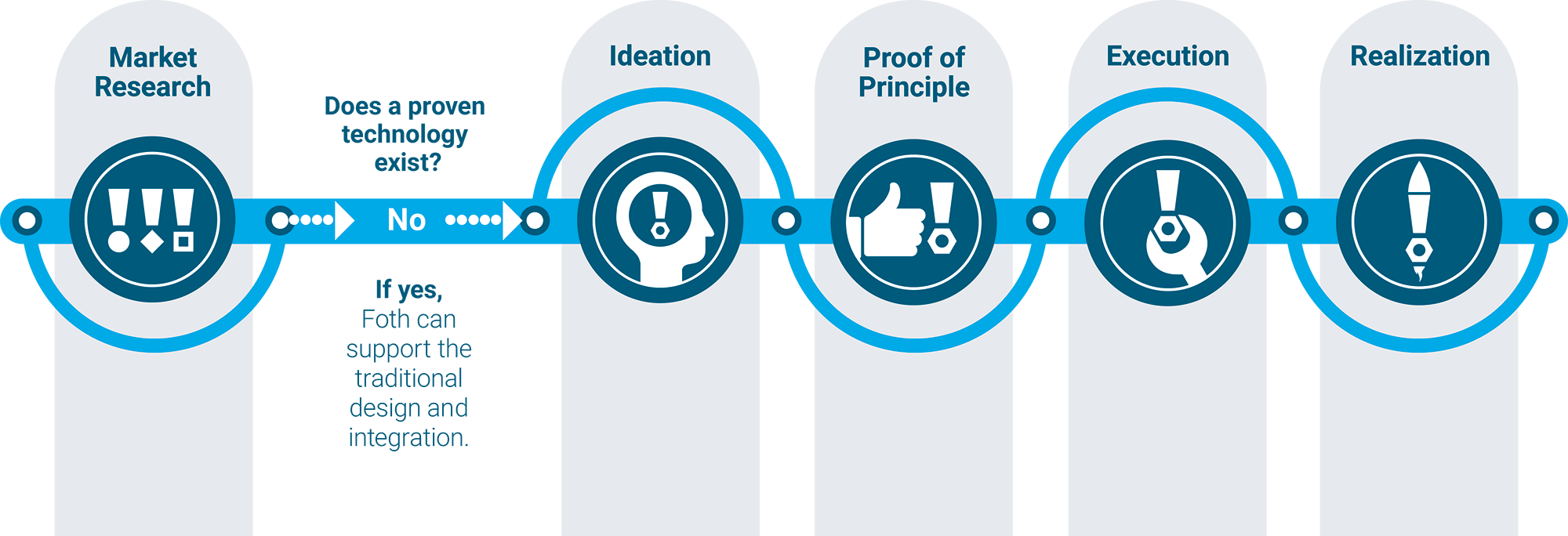

Serial 1 Automation – A Proven Process

Market Research

Our teams investigate whether proven technologies are available in the market. If yes, we can support with traditional design and integration. If no, we advance to ideation.

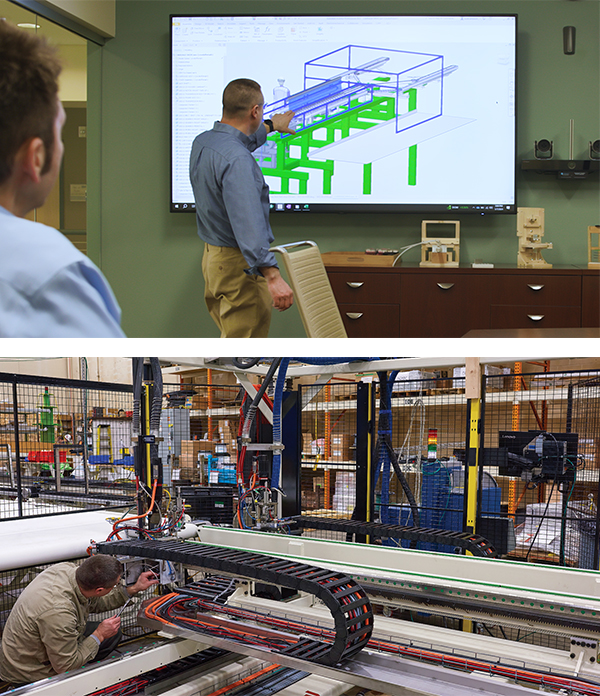

Ideation

We conduct a series of brainstorming, conceptualization, and options analysis to understand risk vs. reward, viability, and cost estimates

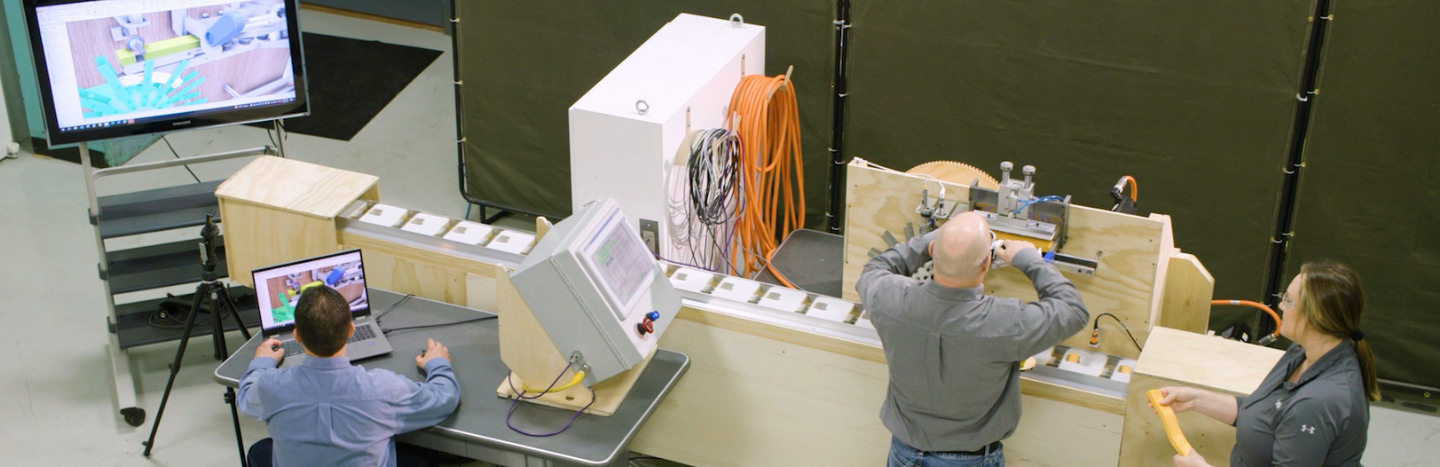

Proof of Principle

We take the concept into a prototype phase in our lab and fabricate functional models for testing. Risk is reduced by stress testing the most challenging aspects before making a “go / no-go” decision.

Execution

A final design is created to guide fabrication, assembly, and controls programming. Then, you are invited to a factory acceptance test (FAT) visit.

Realization

Your new equipment is packaged and shipped to your facility. We provide installation and integration, startup support and handoff to operations, and training before the warranty period begins.

Reach Out to Learn More

Ready to derisk and redefine custom automation? Let’s get started.